In our previous article, we talked about different types of machines which are not CO2 laser cutters. But since we offer CO2 laser cutters here at Smoke&Mirrors, let's get down to understanding what exactly we are dealing with!

A BRIEF HISTORY ON LASERS...

First of all, "LASER" is actually an acronym! It stands for "Light Amplification by Stimulated Emission of Radiation."

The first ever working laser was built by Theodore Maiman at Hughes Research Laboratories in California. The laser medium used was synthetic ruby, and this laser emitted a deep red beam. However, the news of the development of a laser was met with skepticism, and the laser was described as “a solution looking for a problem.”

The CO2 laser and gas laser cutting process using a CO2 mixture was invented by Kumar Patel at Bell Labs in New Jersey. The CO2 laser was found to be cheaper and more efficient than the ruby laser.

HOW DO THEY WORK THOUGH?

There are two main CO2 laser types used in small to medium size laser machines, commonly referred to as DC (Direct Current; or ‘glass’ tubes) and RF (Radio Frequency; also called ‘metal’ or ‘ceramic’ lasers). While DC is a water cooled system, RF works with an air cooled system.

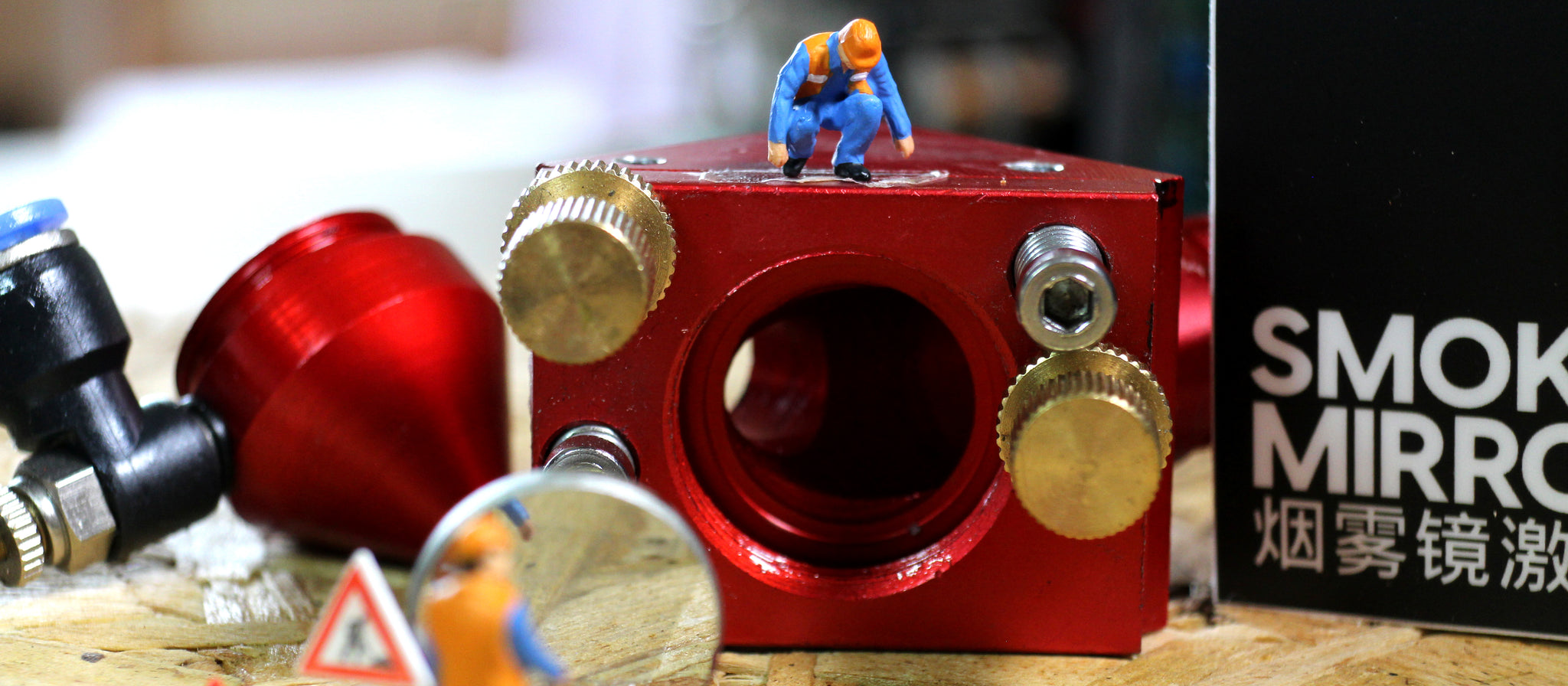

Either way, the output mechanism works as shown below about the same way:

One of the differences between DC and RF systems is the kerf width when cutting (width of slit made by the laser), which will end up to be narrower on an RF laser. The beam of a DC machine is elliptical, and the RF will produce a rounder beam which allows for the before mentioned kerf tightness. A good quality DC laser cutter can produce nearly the same output as an RF laser cutter, however the visible difference that we meant above is best observed through a microscope. These days, both DC laser cutters and RF laser cutters are more available to the common populace at a price they can afford.

The firing of CO2 laser cutting machines consist of CO2 gas along with a mixture of other gases like helium and nitrogen. This type of gas mixture is charged up by electric discharge which then produces the laser beam. The wavelength of such cutters is 10.6μm.

There are three kinds of operations you can do with your laser cutter:

Laser Cutting: when the material is cut in a clean line produced by a powerful laser beam, and completely penetrates through the workpiece.

Laser Marking: this operation does not completely penetrate the material; only the appearance and properties of the material gets changed by the heat of the beam.

Laser Engraving: an operation that removes the material from the surface leaving an embossing/cavity behind with your design. The heat of the laser first melts the material and then vaporizes it immediately to create sharp impressions.

What can you cut, mark and engrave with your CO2 laser cutter?

About anything that could be of household use!

This includes wood, certain plastics, leather, paper and card, some fabrics, anodised aluminium or metals coated properly, and even glass under certain circumstances and safety precautions.