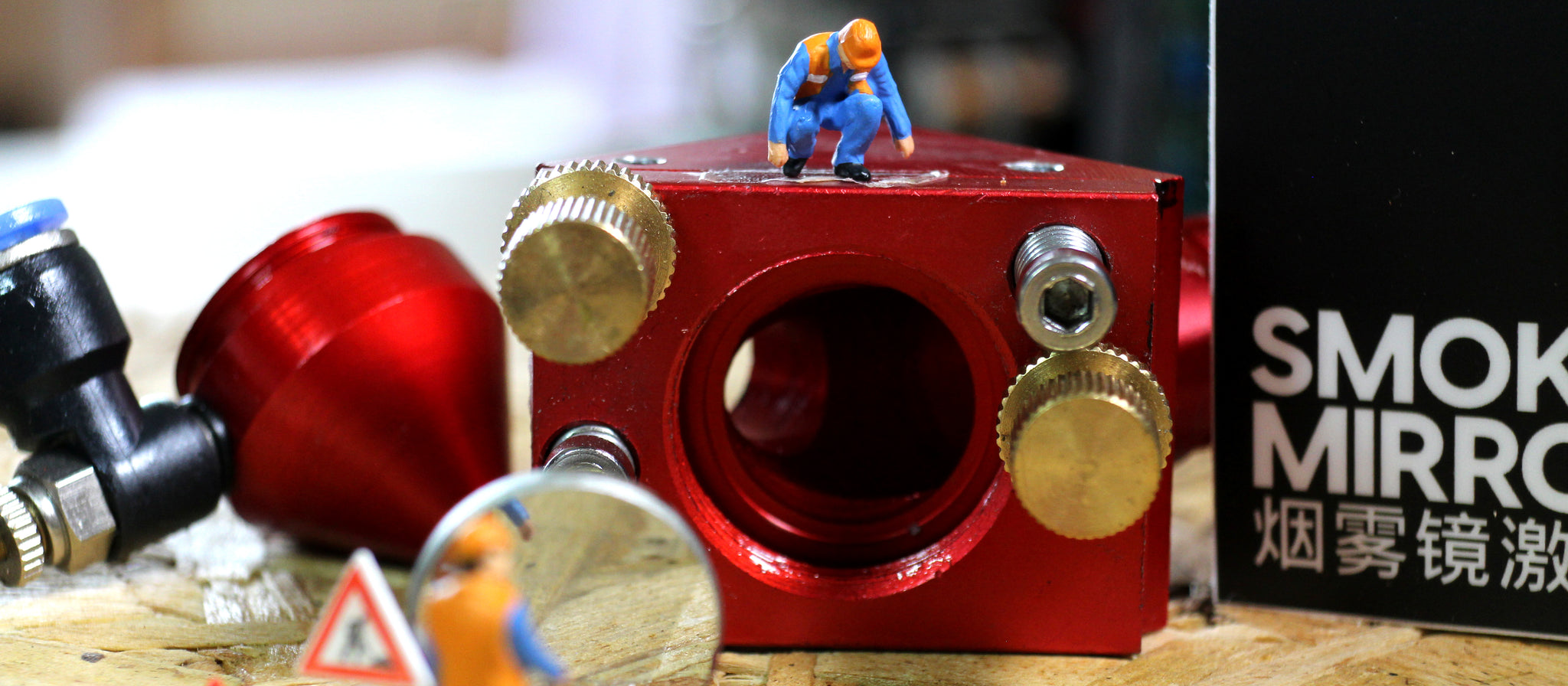

Here at Smoke&Mirrors, we deal with water cooled glass-tube CO2 machines up to 100W and offer replacement tubes for your CO2 laser cutter machines. These laser cutters are not as costly to maintain as some of the other machines within the industry, and are generally more user-friendly. Although we will not cover CO2 laser cutters in this article, do stay tuned...!

But what are these other machines?!

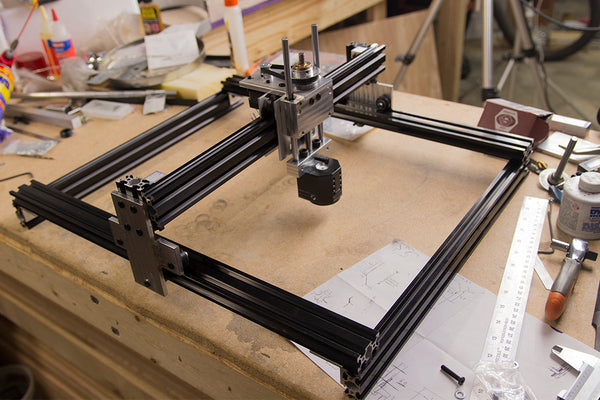

1. Diode Laser Cutters

Diode lasers can range from a simple desktop build to more industrial setups used for skin treatment or other medical procedures. In general what we refer to as "diode laser" is the component within the machine that produces the beam which will then engrave or cut the work piece or surface it is aimed at.

These lasers are also called semiconductor lasers. Light is emitted by passing current through a semiconductor, and that light is used for various applications. They are used widely in our daily life from laser printers to optic disks such as DVDs, etc. These lasers have the advantage of being small and are low voltage, low current, and therefore are often mounted on smaller laser cutters. Diode laser cutters are often cheap and the quality and safety considerations vary wildly, too. Although they are able to cut and engrave materials like wood, diode laser cutters have a difficulty dealing with acrylics.

2. Nd:YAG Laser Cutters

Nd:YAG lasers are optically charged using a flashtube. These lasers typically emit light with a wavelength of 1064 nm, within the infrared spectrum.

This type of technology allows the cutting of non-steels, such as copper, brass, aluminium and aluminium alloys.

3. Fibre Laser Cutters

In fibre lasers, the active gain medium is an optical fibre doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fibre amplifiers, which provide light amplification without lasing.

Fibre laser cutters are able to cut through stainless steel, carbon steel and ceramics as well.

4. RF Lasers

An RF laser uses a metal chamber that contains the laser gas mixture as its "tube". Precisely controlled radio frequency energy is used to create ionised gas plasma for the laser to produce a laser beam. These lasers are designed to operate without high voltage and water cooling.

5. Galvanometer (Galvo) Lasers

Laser cutters which use a Galvanometer or Galvo system use mirror technology to move the laser beam in different directions by rotating and adjusting mirror angles within the boundaries of a work area. Galvo lasers are ideal for using fast speed and intricate fine detailed marking and engraving. It does not need much maintenance; the only maintenance required for Galvo laser is the revision of the lenses.

6. BONUS: Plasma Cutters

Plasma cutters are not to be confused with a "Plasma laser", as that is what we can see in popular cartoons and Sci-Fi shows. As opposed to common belief, plasma cutting doesn’t use fire or a flame. Instead, it uses conductive ionised gas (or simply just air), which is also known as plasma, and its cutting process is characterised by the use of a plasma torch. When activated, the plasma torch will project a mixture of gases, including nitrogen and hydrogen, through the nozzle, which subsequently creates plasma.

This state of material is able to melt (cut) through the toughest of materials.