By its default configuration, engraving metal with a CO2 laser cutter is only possible by adding a few extra steps of preparation before we can actually fire our beams towards the work piece to get any kind of results.

One of the cheapest and the least messy way to engrave metal with your CO2 laser cutter is using a medium such as Dry Molybdenum Lubricant, or Dry Moly Lube in short.

To allow the marking agent to properly bond with the metal, the laser must be run at low-speed and high-power configuration. Users sometimes find that they are able to wipe off the mark after lasering - this tells that the piece should be run again at a lower speed and higher power setting.

The advantage of metal marking with a CO2 laser is that the mark is actually produced on top of the metal without removing material, so there is no impact on the metal’s tolerance or strength. Coated metals, such as anodized aluminum or painted brass, don't need pre-treatment.

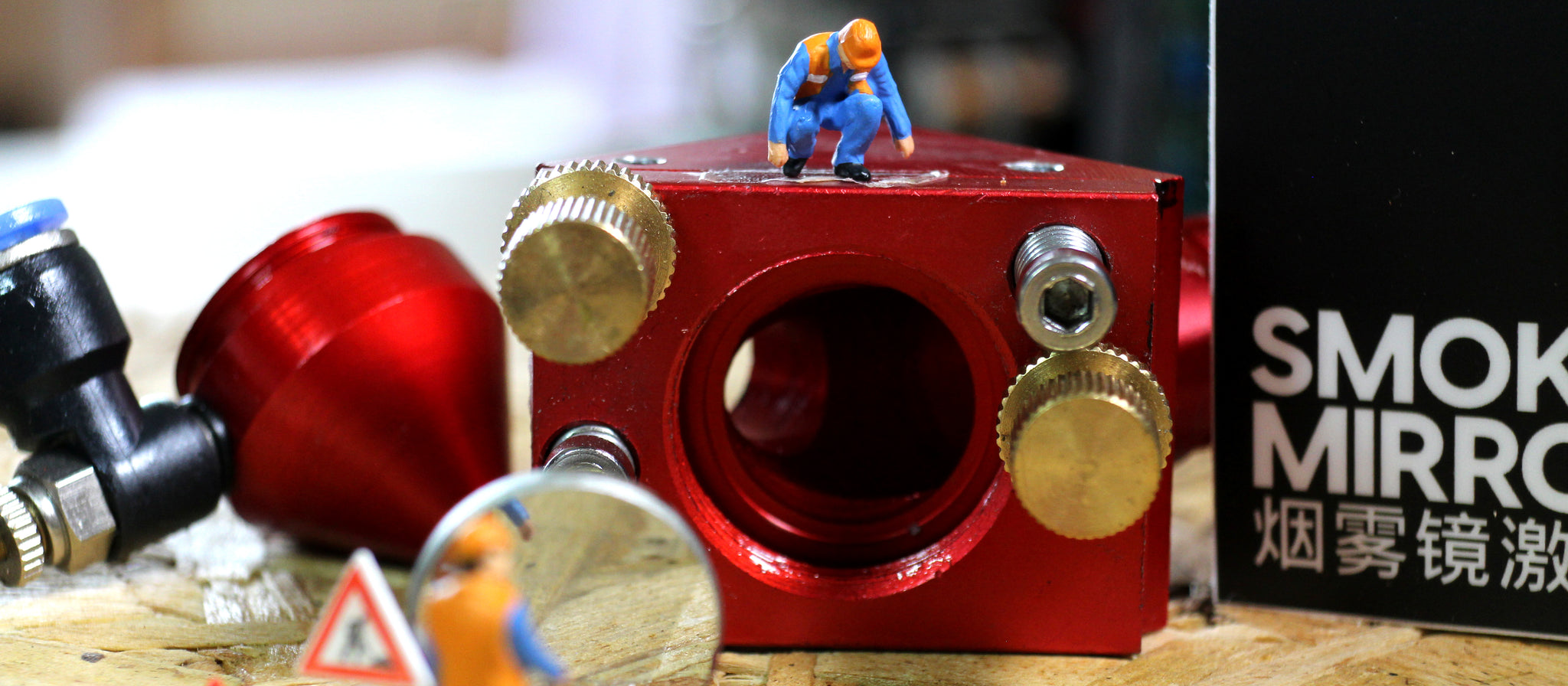

However, if you are like us and love innovative technology (and have the budget for it), a sure-shot way to engrave your metal work piece with your CO2 laser cutter is by using a CerMark Spray. We recently received a sample of this cool product, and tried it out right away. The results were shocking!

But how does it actually work?

CerMark marking materials consist of traditional ceramic glazing material with a twist: a thermal absorber. The ceramic glazing material is a mixture of with pigments for coloring, and glass frit: small particles of partially fused glass designed to melt at a much lower temperature than ordinary window glass.

CerMark's own method called TherMark uses a laser as the heat source to fuse the ceramic glaze instead of a kiln. All this happens in microseconds as opposed to hours, consuming far less “energy” and without compromising or damaging the material being marked. It is the thermal absorber within the TherMark marking materials which enhances and speeds the heat absorption from the laser beam, improving the transfer to the glaze. The thermal absorber also serves in allowing the substrate to be marked using multiple laser types. As we know, a CO2 laser cannot mark most metal because the beam cannot be absorbed by the substrate. Because of the absorbers, TherMark facilitates marking metals with a CO2 laser, increasing the range of applications the laser system is capable of.

Although not the cheapest on the market (and being the only brand currently that produces such engraving chemical), we were so stoked at the results that we would recommend to have a go at CerMark's products if you get the chance.

Are you looking to buy a laser cutter? Take a look at our range of machines, and let's get in touch if you would like more information.